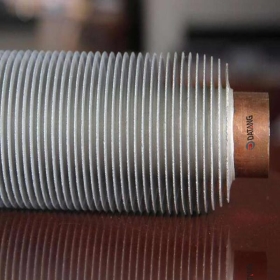

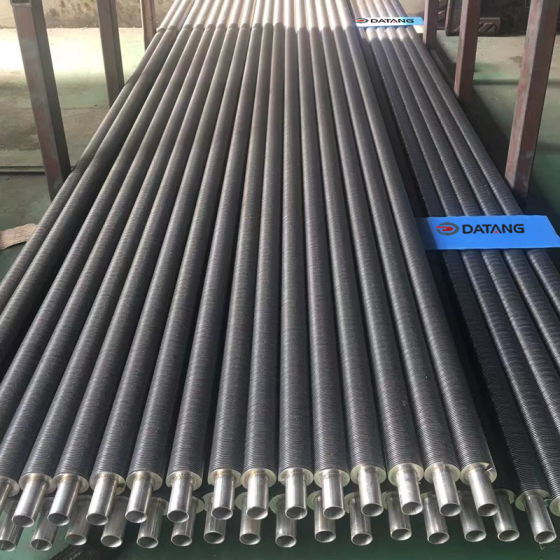

Finned Copper Tube Customizable Extruded Finned Tube Fin Pipe for Boiler Economizer

나는. Excellent Thermal Conductivity

-

Material Properties

Copper is renowned for its outstanding thermal conductivity. As a metal with a high thermal conductivity coefficient, 사용을 시작할 준비가 된 지느러미 튜브 it enables rapid heat transfer within the finned copper tube. 예컨대, in air conditioning and refrigeration systems, finned copper tubes can quickly absorb heat from indoor environments and transfer it outdoors, resulting in rapid cooling.

The fins attached to the copper tube further enhance this property. By significantly increasing the surface area available for heat transfer, they facilitate more efficient heat exchange between the tube and the surrounding fluid or gas. -

Structural Contribution

The design of the fins on the copper tube is crucial in maximizing heat transfer efficiency. The increased surface area provided by the fins allows for a greater contact area with the heat transfer medium, enabling more effective heat exchange. This is particularly beneficial in applications where a large amount of heat needs to be transferred in a short period of time, such as in industrial heat exchangers or power generation systems.

2 세. Superior Machinability

-

Ease of Forming

Copper has excellent malleability and ductility, making finned copper tubes easy to form during the manufacturing process. Whether through extrusion, 용접, or other processing methods, it is possible to produce finned copper tubes in various shapes and sizes to meet the specific requirements of different applications. 예를 들어, finned copper tubes can be customized to fit into the limited space of small household appliances or electronic devices, ensuring efficient heat dissipation.

The reliable connection between the fins and the copper tube is also essential. Copper’s good weldability ensures a strong bond between the fins and the tube, enabling effective heat transfer and withstanding pressure and vibration, thereby enhancing the product’s service life and stability. -

Connection Reliability

In applications where multiple finned copper tubes need to be connected, copper’s weldability and brazing properties allow for easy and reliable connections. This ensures a seamless flow of heat transfer medium and minimizes the risk of leaks or heat loss at the connection points. 또한, copper’s compatibility with various joining methods makes it suitable for a wide range of installation scenarios.

3세. Strong Corrosion Resistance

-

Material Stability

Copper is relatively stable at room temperature and is not easily oxidized. This chemical stability gives finned copper tubes good corrosion resistance. Even in harsh environments with moisture, certain acidity or alkalinity, finned copper tubes can maintain their performance and are less susceptible to corrosion.

For applications in corrosive environments, surface treatments such as nickel plating or chromium plating can be applied to further enhance the corrosion resistance of the finned copper tube. These surface coatings form a protective layer on the copper tube, preventing corrosion and extending the service life of the product. -

Surface Treatment Options

In addition to traditional surface treatments, advanced coating technologies can also be used to improve the corrosion resistance of finned copper tubes. 예를 들어, polymer coatings or ceramic coatings can provide additional protection against corrosion and wear. These coatings can be tailored to specific application requirements, offering enhanced performance and durability.

정맥. Compact Structure and Light Weight

-

Compact Design

The structure of finned copper tubes is designed to be compact. 열교환기: 효율적인 열 전달의 중추 The fins are closely attached to the copper tube, minimizing the space occupied by the product. This is particularly advantageous in applications where space is limited, such as in small electronic devices or portable cooling systems. The compact design allows for efficient heat transfer without sacrificing valuable space.

Finned copper tubes are relatively lightweight compared to some other heat transfer materials. This makes them easier to handle and install, reducing labor costs and installation time. In applications where weight is a concern, 항공 우주 또는 자동차 산업과 같은 분야, finned copper tubes offer a lightweight solution without compromising on heat transfer performance. -

Lightweight Advantage

The combination of copper’s density and the compact design of the finned tube results in a product that is both efficient and lightweight. This makes finned copper tube tubes a preferred choice for many applications where weight and space constraints are important factors. 또한, the lightweight nature of finned copper tubes can contribute to energy savings in transportation and installation processes.

dtfinnedtube.com

dtfinnedtube.com

위챗

WeChat으로 QR 코드 스캔