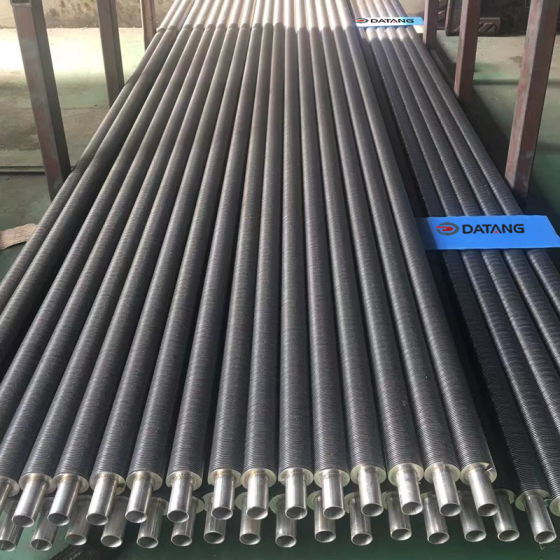

Hot Dipped Galvanized Finned Steel Tube for Greenhouse Air Heating

1.Structural features

- Fin design

- Finned steel tubes are characterized by the presence of fins attached to the outer surface of the steel tube. Hot Dipped Galvanized Finned Steel Tube for Greenhouse Air Heating These fins can be of various shapes and sizes, such as rectangular, circular, or helical. The fins significantly increase the surface area available for heat transfer. For example, in a helical finned steel tube, the fins are wound around the tube in a spiral pattern. This design can provide a much larger surface area compared to a plain tube, sometimes up to several times larger depending on the fin density and height.

- The fins are usually integrated with the tube through processes like welding or extrusion. In welded finned tubes, the fins are precisely attached to the base tube using advanced welding techniques, ensuring a strong bond. This allows for efficient heat conduction from the tube to the fins and then to the surrounding medium.

- Material and Construction

- The base material of finned steel tubes is steel, which offers excellent strength and durability. Stainless steel is a commonly used material due to its corrosion – resistance properties. It can withstand exposure to a wide range of chemicals, moisture, and other corrosive agents. This makes finned steel tubes suitable for use in harsh environments such as industrial plants, where they may be exposed to chemicals during heat – exchange processes.

- The construction of the tubes is designed to ensure a high level of structural integrity. The wall thickness of the tube is carefully selected to balance strength and heat transfer efficiency. Thicker walls can provide more strength but may slightly reduce heat transfer rates, while thinner walls can enhance heat transfer but may require more careful handling to avoid damage.

2.Heat transfer advantages

- Enhanced Heat Transfer Efficiency

- The increased surface area provided by the fins is the key factor in improving heat transfer efficiency. Heat is transferred from the fluid inside the tube to the tube wall and then to the fins. The larger the surface area of the fins, the more heat can be dissipated or absorbed. In applications such as heat exchangers, this means that a greater amount of heat can be transferred between two fluids (e.g., a hot fluid inside the tube and a cooler fluid outside the tube) in a shorter period of time.

- The finned design also helps to break up the boundary layer of the fluid surrounding the tube. The boundary layer is a thin layer of fluid that can act as a thermal resistance, slowing down heat transfer. The fins disrupt this layer, promoting better mixing of the fluid and enhancing the convective heat transfer coefficient. As a result, the overall heat transfer rate can be significantly improved, sometimes by as much as 2 – 3 times compared to a non – finned tube, depending on the operating conditions and fin geometry.

- Temperature Uniformity

- Finned steel tubes can also contribute to better temperature uniformity. In a heating or cooling process, the fins help to distribute the heat more evenly along the length of the tube. For example, in a greenhouse air – heating system using finned steel tubes, the fins ensure that the warm air is spread more uniformly throughout the greenhouse. This is beneficial for applications where consistent temperature is crucial, such as in industrial drying processes or in maintaining a stable temperature environment for sensitive equipment.

3. Performance Advantages

- Durability and Longevity

- The steel construction and often the use of stainless steel make finned steel tubes Unlocking the Power of Heat Exchanger Heating highly durable. They can withstand high – pressure and high – temperature conditions without deformation or failure. In industrial processes that involve repeated heating and cooling cycles, such as in power plants or chemical refineries, the tubes can maintain their structural integrity and heat – transfer performance over a long period of time.

- The resistance to corrosion also adds to their longevity. This means that finned steel tubes require less frequent replacement compared to tubes made of less durable materials. They can be used in outdoor applications, such as in HVAC systems exposed to the elements, without significant degradation due to rust or other forms of corrosion.

- Versatility in Applications

- Finned steel tubes are extremely versatile and can be used in a wide range of applications. In the heating, ventilation, and air – conditioning (HVAC) industry, they are used in air – handling units, radiators, and heat pumps to transfer heat between air and refrigerant or water. In industrial settings, they are used in heat exchangers for processes such as oil refining, chemical production, and food processing. They are also suitable for applications in power generation, such as in steam condensers and gas – to – liquid heat exchangers.

- Their ability to handle different fluids and operating conditions makes them a preferred choice in many industries. For example, they can be used to transfer heat between water and air, or between different types of oils and gases, depending on the specific requirements of the process.

- Cost – Effectiveness

- Despite their advanced design and high – performance capabilities, finned steel tubes can offer cost – effective solutions. The enhanced heat transfer efficiency means that smaller and more compact heat – exchange systems can often be used. The All Powerful Tube Type Heat Exchanger: Unraveling Its Secrets This can lead to savings in terms of space requirements and installation costs. For example, in a commercial heating system, the use of finned steel tubes can reduce the size of the heat exchanger, allowing for a more streamlined installation in a limited space.

- Their durability and long service life also contribute to cost – effectiveness. The reduced need for frequent replacement and maintenance can result in significant savings over the long – term. Additionally, the efficient heat transfer can lead to energy savings, as the system can operate more efficiently and consume less energy to achieve the same heat – transfer goals.

WeChat

Scan the QR Code with WeChat